If you notice a change in sales velocity or lead time, rop formula it’s time to set new reorder points. Managing inventory is an essential aspect of many businesses, and knowing when to reorder stock can make the difference between a seamless operation and costly interruptions. One of the critical components of inventory management is determining the reorder point (ROP). The reorder point ensures that new stock is ordered in time to replenish supplies before they run out.

- They need the average daily usage of the medium, blue, variant of one of their popular sweaters from this past month.

- All of these errors must be “backed out” to maintain an accurate depth record.

- Safety stock is crucial for protection against unexpected events, such as stockouts at your supplier or a surge in demand.

- Multiply this number by the maximum number of days it could take a supplier to deliver new inventory to you.

- By adjusting your reorder point based on this data, you can ensure that you maintain optimal stock levels without being caught off guard by sudden spikes or drops in demand.

recommendations for setting up reorder points

Still, that is in the perfect world, so organizations must consider the risks. Complicating inventory management further, the ideal amount of safety stock can also swing depending on market trends or supply chain disruptions. Accurate demand forecasting can help you predict these shifts in advance so you can alter your strategies to accommodate these changes.

ShipBob keeps reorder points simple

In other cases, it can be added to your existing safety stock if late deliveries are a valid concern. That ensures you have enough stock to meet sales during the lead time, plus some extra safety stock to handle any surprises like sudden spikes in demand or delays in your supply chain. If a business wants to keep five days of additional stock, it will calculate its average demand over five days and set that as the safety stock level. Five days stock at average demand is 1,000 units so they will set https://www.bookstime.com/ their safety stock at 1,000. In a business, you can’t afford to run out of stock or hold too many items in yourinventory. You need to maintain an equilibrium between ordering items at the right timeand keeping the right number of items as buffer stock.

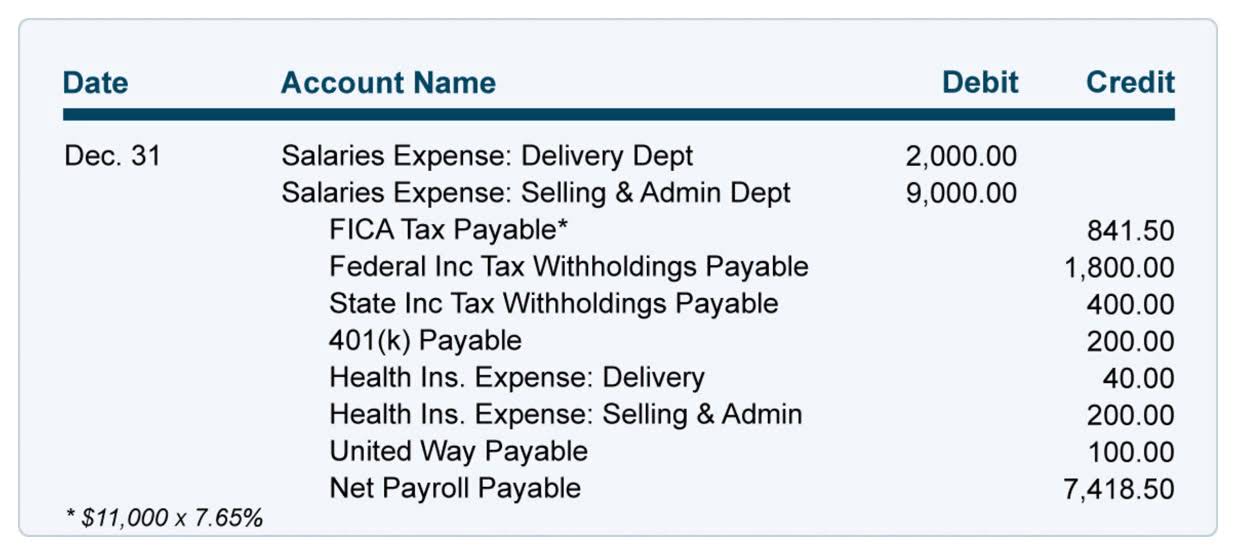

Basic safety stock formula

By providing accurate, up-to-date data, these systems improve decision-making and allow businesses to restock at the optimal time, preventing both overstocking and understocking. With advanced reporting tools, managers can make better strategic decisions, further enhancing supply chain management and overall operational efficiency. The Reorder Point (ROP) is crucial not only for keeping inventory stocked but also for impacting various aspects of business operations and financial health. A well-calculated ROP minimises inventory management costs by reducing holding expenses and avoiding costly stockouts. It plays a key Accounting Errors role in maintaining customer satisfaction by ensuring products are available when needed, thereby preventing lost sales and customer defection. For operational continuity, particularly in manufacturing, an effective ROP prevents disruptions caused by running out of materials or goods.

Achieve your inventory objectives with reorder points

- If you notice a significant increase in customer demand, it may be time to restock sooner than expected.

- As per a study, it was suggested that retailers lose 4% of their annual sales on average arising out of stockout situations.

- Getting accuracy in finding the reorder point in inventory control has the following advantages.

- In this scenario, demand is steady and fully predictable, meaning there’s no need for a safety stock buffer, and service levels will always remain at 100%.

Storing more inventory than what can be sold in a timely fashion is not a productive use of capital. Reorder points provide businesses with greater financial flexibility by allowing them to keep a minimum amount of inventory on hand without running out of product. Reorder point calculators are a convenient choice if you have a large inventory with many SKUs. One may be a part of the inventory management software you use or you can use an Excel sheet with built-in formulas. This is the point at which you need to order product to replenish your stock. Generally, it is best practice to review reorder points every three to six months.